Poultry Management System in Poultry Farms

With the development of the poultry industry, the scale and mechanization are getting higher and higher, and the productivity level is constantly improving. Traditional manual management can no longer meet the needs of large and medium-sized chicken farms. Therefore, the chicken management system of the traditional poultry industry enables the application of chicken production management to be systematically integrated, and digital chicken farm monitoring networks and information aggregation interactive platforms have emerged. To a large extent, information in chicken production can be obtained and circulated in a timely manner, thereby transforming the chicken production model from the traditional logistics management core to the information flow management core.

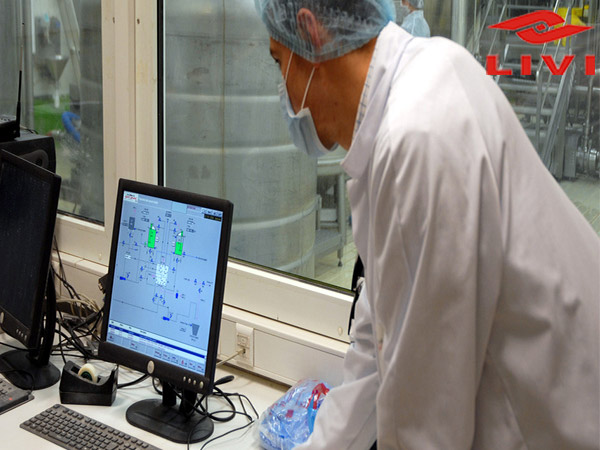

Poultry farming equipment and poultry equipment supplies can be an automated management system in a poultry management system. Livi Industry will provide this automated poultry management system for your poultry farm. Livi’s poultry farm management system is an intelligent electrical cabinet system. It is an automated system that is especially suitable for standard poultry cage systems. The purpose of the electrical cabinet is to control the operating process of horizontal exhaust fans, longitudinal exhaust fans, cooling pads, pumps, and feed conversion.

Compared with manual operation, the automated chicken management system has many advantages such as high efficiency, accuracy, and labor cost savings, and is widely used in large-scale chicken farming industrial enterprises. However, in relatively small-scale chicken farming enterprises or relatively simple chicken farming industries, this technology is rarely used, or there is no complete automated chicken management system. For example, some chicken farms currently place thermometers or hygrometers in the chicken house to monitor the temperature and humidity of the chicken house. When the temperature or humidity of the chicken house is not appropriate, it will not be adjusted manually to achieve comprehensive control of the entire production plant, which brings about problems of inefficiency, time-consuming and labor-intensive.